I found this necklace hidden in a hanging door on a jewelry box that I never open. It is strung on foxtail. I went over it with a loupe and you can see and feel the matrix. I took plenty of pictures so I’ll try to use the best. I will appreciate your opinions. Thanks ![]()

That looks to me like hard, natural turquoise.

Thanks. That was my feeling too but I was so surprised by finding it that I wanted to make sure I wasn’t imagining things. No recall at all about where I got it. It’s feeling rather like Christmas. Any guesstimate about value?

This would be very difficult to pull off with natural turquoise, @Islandmomma. I’d place odds at 90+ % the material is stabilized.

@Islandmomma Those are good photos. Looks like real-deal, natural turquoise to me.

A surprise is always nice. Do I dare say Bisbee? Sure looks like the Bisbee nuggets Alltribes is selling. Just my guess.

I can certainly understand that. So other than stabilized is it pretty decent turquoise? Thanks

Would there be a non-destructive or least destructive method to determine stabilized or not?

Boy that would be a real nice surprise!

Help me to understand, please. Your comment is in reference to the drilling through of the turquoise nuggets? If the nuggets weren’t stabilized, the turquoise would most likely break or shatter? Thanks!

Color looks great. Stabilization is often used because it seals up and chemically binds any faults or tiny fractures that arise when the piece is shaped and drilled. The wafer stones are particularly subject to breakage.

Yes. That’s correct @Patina. Ultrasonic drilling in particular is hard on natural stones.

Lighter test. Pass a flame lightly over the stone a couple of times lingering just long enough to release some of the polymer binding permeating the stone, then take a whiff. You can usually smell traces of the polymer with a treated or stabilized stone. Provided you don’t leave the flame in one place long enough to scorch or discolor the stone, this is a non-destructive process.

Treating and stabilization use the same process of permeating the the stone with a polymer resin. Stabilizing doesn’t add color whereas treating does add color.

It’s completely fake, I will PM you my address so I can wear…errr, dispose of it properly (j/k)

That’s quite lovely @Islandmomma ![]()

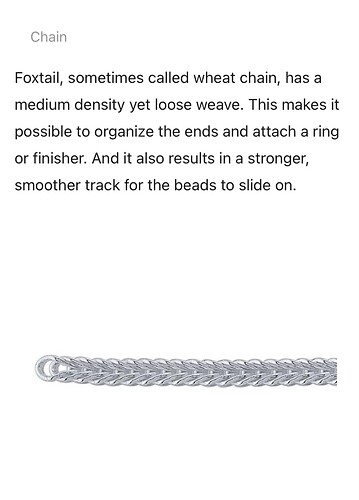

Sorry if this seems nitpicky, but this is not what I think of as foxtail. Foxtail is a metal chain that looks like this (screenshot taken from Horsekeeping):

Your necklace is strung on a thinner beading wire which I believe is then coated with a clear plastic layer, something like this:

Beading wire can be finished with crimp beads as your necklace is; foxtail would require the addition of jump rings or possibly soldering.

I have never seen any type of turquoise strung on foxtail. It’s thicker so would require a wider hole (more turquoise loss and more risk for breakage with drilling), and the metal chain would be very abrasive and damaging to the turquoise, even if stabilized (I believe). Foxtail is really better suited for metal beads. I’ve also never seen natural turquoise strung on anything but cotton string or cord, as this would be least damaging to the fragile natural beads. So the stringing and finishing materials on this necklace were what first led me to believe it was not natural turquoise.

Thanks for that info, @OrbitOrange. Now I need to check a couple of my necklaces that I’ve always suspected are stabilized, but wasn’t sure. I also had in the past read what mmrogers stated; worked beads are less likely to be natural, because a really hard natural stone would be needed to stand up to being carved/shaped.

Just wanted to add that from ± 56 beads that i drilled i had about 3 shatter. I was surprised by this, expected more trouble. They were Persian and Royston natural. (i’ve read that Royston generally is a harder type of turquoise, which might have to do with it)

Economically, using natural stone for carved beads is impractical for production purposes due to the tendency of natural stones to fracture and break in processing. Ultrasonic drills are typically used to drill the stones for stringing. High frequency vibrations, water, and grit is used rather than rotary drilling, and the high frequency vibration is very hard on micro faults and fractures found within natural turquoise stones.

Thanks. I didn’t look at it closely, I just checked for cord and was surprised that it was strung on wire. Thanks for pointing it out. I actually have some beading wire here that my dad gave me.

Would a rotary drill be easier on the turquoise?